Enterprises rely on different types of information systems (IS) for managing day-to-day business and making decisions such as customer relationship management systems (CRM), enterprise resource planning (ERP) and supply chain management (SCM) systems. Businesses rely on ERP systems to automate business operations, replace their legacy systems, and integrate core business processes and to help adding value and visibility. SCM systems help organizations to enhance relationships with supply chain members and stakeholders. Therefore, the integration between ERP and SCM systems is a key to accelerate business performance.

SCM - Supply Chain Management and ERP - Enterprise Resource Planning have been gaining popularity among organizations over the last few years, across a number of vertical industries in USA and globe. Software development companies in USA have started their focus into developing software like SCM, ERP and business solutions.

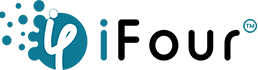

An ERP system focuses on the management of business information by integrating disparate systems across functional groups such as inventory control, procurement, distribution and finance. A Supply Chain Management system links in supply chain partners who help a company find the raw materials it needs to assemble/manufacture the products and services and deliver it to its customers.

The integration of Supply chain management and ERP system allows distribution and manufacturing organizations the capability to gain greater visibility of its operations. Also increasing speed, efficiency and overall customer satisfaction.

Need of Supply Chain Management (SCM) System

-

Managing contractual obligations that ensures a continuous supply and avoiding a service company’s delivery disruptions during business hours

-

Strengthening supplier relations for systematic synergy with suppliers and different lines of businesses.

-

Managing risk and compliance to abide by organizational as well as industry specific compliances and regulations.

-

Enterprise spending management that ensures procurement happens through the right suppliers and reduces overall costs.

- Establishing a single comprehensive supplier view and deriving insightful procurement analytics

Software development companies have developed many applications for TMS, WMS etc. to manage supply chain of the organization..

Supply Chain Management-Key Elements

Supply Chain Management consists of four phases viz. design, planning, execution, control and monitoring of supply chain events with the aim of creating value to build a competitive infrastructure. This enables the organization to leverage worldwide logistics. It not only synchronizes supply with demand, but also measures performance globally. A Supply Chain Management (SCM) system provides real-time perceptibility into operations, and integrates activities through improved supply chain relationships. This enables organizations to achieve a sustainable competitive advantage. Following are the four key elements for Supply Chain Management.

a) Supply Chain Planning

Supply chain planning is done to determine the set of policies and procedures that govern the operation of supply chain. Planning also includes the determination of marketing channels, promotions, respective quantities and timing, stock level and replenishment policies and production policies. Planning majorly establishes the factors within which the supply chain should operate.

b) Supply Chain Execution

Requirement of Execution-oriented software applications for effective procurement and supply of goods and services throughout a supply chain. It covers manufacturing warehouse and transportation execution systems, and systems that provide visibility across the supply chain.

c) Supply Chain Monitoring

Monitoring is the ability to review the supply chain activities in real-time. It can be either to identify the status of specific activities or review overall performance.

d) Supply Chain Measurement

Measurement is evaluation of the actual activity against planned targets. This is often used with scorecards of benchmarks so that unfamiliar or undesirable variances can be identified and investigated.

Integration of ERP and SCM

ERP (Enterprise Resource Planning) and SCM (Supply Chain Management) systems provide various benefits to an organization in terms of capabilities and functionalities. The integration provides both intra-organizational and inter-organizational advantages. It also provides substantial leverage over competitors. The integration of ERP and SCM systems can be made easier with the following considerations:

- Business priorities: Which one to implement first: ERP or Supply chain? In most cases, ERP starts with financials and business workflow, and companies build on from here.

- Technology issues:If the ERP and SCM systems are on similar technology platforms, integration is easier to execute. Hence, decreasing time to ROI (Return On Investment).

- Cost of implementation:Companies must consider and evaluate the cost impact of both systems being integrated.

- Total cost of ownership (TCO): There may be cost savings and also better user experience if both systems processes are merged to reduce the points of data capture.

Benefits of Integrating ERP and Supply Chain Systems

Software development companies play a major role in integration of ERP and supply chain systems. If most projects follow some simple rules, companies can increase the chance of its success, deliver on time, and proudly involve the relevant group of users who utilize the system to maximum gain. Some benefits of integration of ERP and Supply Chain Management system are as follows:

- Improved efficiencies, lower costs and improve productivity

- Increased customer retention as it has the ability to provide better services to customers

- Increased capability to manage resources through a streamlined process or an automated workflow

- Enhancement of speed of tasks and increase in production by leveraging IT

- Enabling organization to compete more effectively by providing ability to deal with with business changes in the future and to adapt to changing rules and regulations

One Stop Solution ERP Software Development Company - Contact Now

Conclusion

ERP and Supply Chain Management systems offer various benefits to an organization in terms of capabilities and functionalities. The ERP system provides intra-organizational and Supply chain provides inter-organizational advantages, integration of both systems will provide a company with substantial leverage over competitors. This will also enable the organization to stand globally in the market as the organizations gets inter as well as intra organizational advantages.

Reference

http://archive.thoughtsoncloud.com/2014/06/need-supply-chain-management-system-today/

http://searchmanufacturingerp.techtarget.com/tip/SCM-systems-vs-ERP-systems

https://www.compudata.com/understanding-the-role-of-erp-in-supply-chain-management/